Cascade testing for a subsonic compressor linear cascade and its modification

-

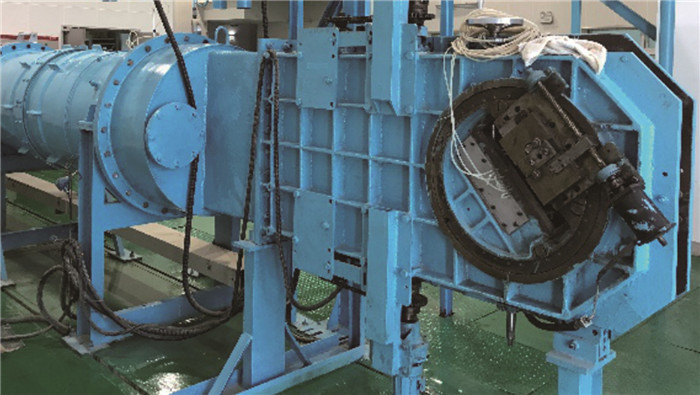

摘要: 为了对比某压气机原始叶型及其改型后的短弦叶型的气动性能,基于某高亚声速叶栅风洞对原型和改型叶型开展了平面叶栅吹风试验。试验前对不带叶栅和带叶栅试验件下试验段进口均匀性和出口周期性进行检查,确定满足试验要求的测量通道。通过吹风试验测量并分析原型叶栅和改型叶栅的出口总压、出口气流角以及叶片表面等熵马赫数分布。结果表明:相对于原始叶型,弦长缩短后叶型吸力面型线曲率变化增大,峰值马赫数后的气流逆压梯度较大,因此附面层内的气流分离损失更大;设计马赫数0.6时,短弦叶栅的低损失攻角范围比原型叶栅减小了约3°,改型叶栅和原型叶栅均表现出较好的负攻角特性;设计攻角下(i=0°),进口马赫数从0.4增大至0.7时,两套叶栅出口尾迹的深度逐渐增大,但尾迹宽度基本不变;达到或者超过临界马赫数0.8之后,原型和改型叶栅的尾迹宽度和深度均显著增大。Abstract: In order to compare the aerodynamic performance of a compressor airfoil and its modification airfoil with short chord, the linear cascade tests for the baseline and modified airfoils were conducted in a high subsonic cascade wind tunnel. Before the formal experiment, the inflow uniformity and outflow periodicity were checked under the test condition with and without the test cascade, and the measurement blade passage was determined to meet the test requirement. By cascade experiments, the outlet total pressure, outlet flow angle, and the isentropic Mach number distribution on the baseline and modified cascades were obtained and analyzed. The experimental results show that the loss of the modified cascade is larger than that of the baseline, due to the larger adverse pressure gradient after the peak isentropic Mach number position caused by the larger curvature change of the modified cascade. At the design inlet Mach number 0.6, the incidence range with low total pressure loss of the modified cascade is three degrees larger than that of the baseline cascade, and both the baseline and the modified cascades show good loss characteristics under negative incidence condition. At the design incidence angle (i=0°), the wake profile depth of the baseline and modified cascades increases with the inlet Mach number 0.4~0.7. But when the inlet Mach number reaches the critical value of 0.8, both the depth and the width of the wake profile of the baseline and the modified cascades increase.

-

表 1 叶栅设计参数

Table 1. Design parameters of test cascades

设计参数 C01 C02 进口几何角β1k/(°) 43 43 出口几何角β2k/(°) 2.0 1.8 进口马赫数Ma1 0.6 0.6 安装角/(°) 21.5 21.4 弦长/mm 55.5 47.2 展弦比 1.8 2.1 稠度 1.4 1.3 叶片数 8 8 -

[1] DUNAVANT J C, EMERY J C, WALCH H C, et al. High-speed cascade tests of the NACA 65-(12A10)10 and NACA 65-(12A2I8b)10 compressor blade sections[R]. NACA RM-L55I08, 1955. [2] EMERY J C, DUNAVANT J C. Two-dimensionalcascade tests of NACA 65-(CloA10)10 blade sections at typical compressor hub conditions for speeds up to choking[R]. NACA RM-L57H05, 1957. [3] LEGGETT J, PRIEBE S, SANDBERG R, et al. Detailed investigation of RANS and LES predictions of loss generation in an axial compressor cascade at off design incidences[C]//Proceedings of ASME Turbo Expo 2016: Turbomachinery Technical Conference and Exposition. 2016. doi: 10.1115/GT2016-57972 [4] LI R Y, GAO L M, MA C, et al. Cornerseparation dynamics in a high-speed compressor cascade based on detached-eddy simulation[J]. Aerospace Science and Technology, 2020, 99: 105730. doi: 10.1016/j.ast.2020.105730 [5] LI J B, JI L C, YI W L. Experimental and numerical investigation on the aerodynamic performance of a compressor cascade using blended blade and end wall[C]//Proceedings of ASME Turbo Expo 2017: Turbomachinery Technical Confe-rence and Exposition. 2017. doi: 10.1115/GT2017-63879 [6] MAO X, LIU B, YUAN F, et al. Numerical and experimental study of separation control by boundary layer aspiration in a highly-loaded axial compressor cascade[J]. Journal of Applied Fluid Mechanics, 2018, 11(2): 433-446. doi: 10.29252/jafm.11.02.27840 [7] YU X J, LIU B J. Research on three-dimensional blade designs in an ultra-highly loaded low-speed axial compressor stage: Design and numerical investigations[J]. Advances in Mechanical Engineering, 2016, 8(10): 1-16. doi: 10.1177/1687814016674629 [8] HERGT A, MEYER R, ENGEL K. Effects of vortex generator application on the performance of a compressor cascade[J]. Journal of Turbomachinery, 2013, 135(2): 021026. doi: 10.1115/1.4006605 [9] KIESNER M, KING R. Multivariable closed-loop active flow control of a compressor stator cascade[J]. AIAA Journal, 2017, 55(10): 3371-3380. doi: 10.2514/1.J055728 [10] 马昌友, 侯敏杰, 凌代军, 等. 平面扩压叶栅流场PIV与三孔尾迹探针对比测试研究[J]. 实验流体力学, 2014, 28(2): 45-50, 58. http://www.syltlx.com/CN/abstract/abstract10717.shtmlMA C Y, HOU M J, LING D J, et al. Comparative study between PIV and three-hole wake probe measurements in the compressor plane cascade flow field[J]. Journal of Experiments in Fluid Mechanics, 2014, 28(2): 45-50, 58. http://www.syltlx.com/CN/abstract/abstract10717.shtml [11] 高丽敏, 高杰, 王欢, 等. PSP技术在叶栅叶片表面压力测量中的应用[J]. 工程热物理学报, 2011, 32(3): 411-414. https://www.cnki.com.cn/Article/CJFDTOTAL-GCRB201103015.htmGAO L M, GAO J, WANG H, et al. Application of PSP technique to pressure measurement on cascade surface[J]. Journal of Engineering Thermophysics, 2011, 32(3): 411-414. https://www.cnki.com.cn/Article/CJFDTOTAL-GCRB201103015.htm [12] 李仁康, 王如根, 何成, 等. 涡流发生器对高负荷压气机叶栅角区分离影响的实验研究[J]. 实验流体力学, 2017, 31(6): 22-28, 36. http://www.syltlx.com/CN/abstract/abstract11062.shtmlLI R K, WANG R G, HE C, et al. Experimental investigation on the effects of vortex generator on corner separation in a high-load compressor cascade[J]. Journal of Experiments in Fluid Mechanics, 2017, 31(6): 22-28, 36. http://www.syltlx.com/CN/abstract/abstract11062.shtml [13] 魏巍, 刘波, 杜炜, 等. 可控扩散叶型与双圆弧叶型实验对比研究[J]. 推进技术, 2017, 38(1): 61-68. doi: 10.13675/j.cnki.tjjs.2017.01.009WEI W, LIU B, DU W, et al. Experimental comparison of controlled diffusion airfoils with double circle airfoils[J]. Journal of Propulsion Technology, 2017, 38(1): 61-68. doi: 10.13675/j.cnki.tjjs.2017.01.009 [14] 高丽敏, 蔡宇桐, 曾瑞慧, 等. 叶片加工误差对压气机叶栅气动性能的影响[J]. 推进技术, 2017, 38(3): 525-531. doi: 10.13675/j.cnki.tjjs.2017.03.007GAO L M, CAI Y T, ZENG R H, et al. Effects of blade machining error on compressor cascade aerodynamic performance[J]. Journal of Propulsion Technology, 2017, 38(3): 525-531. doi: 10.13675/j.cnki.tjjs.2017.03.007 [15] 高丽敏, 蔡明. 压气机叶型的风洞试验研究[J]. 风机技术, 2018, 60(4): 9-15. doi: 10.16492/j.fjjs.2018.04.0002GAO L M, CAI M. Experimental investigations of compressor airfoil on cascade wind tunnel[J]. Chinese Journal of Turbomachinery, 2018, 60(4): 9-15. doi: 10.16492/j.fjjs.2018.04.0002 [16] 刘宝杰, 袁春香, 于贤君. 前缘形状对可控扩散叶型性能影响[J]. 推进技术, 2013, 34(7): 890-897. doi: 10.13675/j.cnki.tjjs.2013.07.006LIU B J, YUAN C X, YU X J. Effects of leading-edge geometry on aerodynamic performance in controlled diffusion airfoil[J]. Journal of Propulsion Technology, 2013, 34(7): 890-897. doi: 10.13675/j.cnki.tjjs.2013.07.006 [17] 向宏辉, 葛宁, 侯敏杰, 等. 高来流马赫数单列叶栅改串列叶栅性能对比试验[J]. 航空动力学报, 2016, 31(11): 2757-2764. doi: 10.13224/j.cnki.jasp.2016.11.026XIANG H H, GE N, HOU M J, et al. Performance contrast experiment of prototype single cascade and redesign tandem cascade at high inlet Mach number[J]. Journal of Aerospace Power, 2016, 31(11): 2757-2764. doi: 10.13224/j.cnki.jasp.2016.11.026 -

下载:

下载: