Experimental study of the fragmentation behavior of a cylindrical liquid jet into crossflow

-

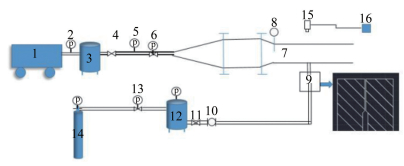

摘要: 本文采用高速相机对低速横向气流作用下的圆柱射流表面波发展及液柱断裂和破碎进行观察研究。实验喷嘴为直射式,孔径为1mm,长径比为20。工质采用水和空气;工况为:温度293K,液体射流速度为2~20m/s,雷诺数为2400~22400,横向气流速度为10~40m/s,气流韦伯数为1.6~25.6,液气动量比为5~127。高速相机帧幅为2000,曝光时间为16s。通过实验观察到横向气流气体韦伯数的变化导致射流破碎形式呈现不同形式变化,液体射流的无量纲表面波波长与气流韦伯数的-0.31幂指数方成正比;主液柱断裂点沿横向气流方向的距离随着液气动量比的增大而减小,而沿初始射流方向的距离随液气动量比的增大而增大;断裂后产生的液滴在沿横向气流方向的速度分量为横向气流速度的0.1倍左右,而沿初始液体射流方向的速度分量先呈现出与液气动量比线性增长关系,直到其变为射流初始速度的0.8倍左右并保持在这一水平。在上述研究基础上,本文拟合了低速射流表面波的波长与气流韦伯数间关系式以及射流破碎位置、射流轨迹及液柱断裂产生液滴的速度与射流初始条件间的数学关系。Abstract: This paper used the high speed camera to observe a cylindrical liquid jet into crossflow and to breakup under the action of wave developments.A direct nozzle has been used, of which the outlet diameter is 1mm and the aspect ratio is 20.The liquid jet in the experiment is water and the crossflow is air.The test temperature is 293K, and the liquid jet velocities are from 2 to 20m/s, with Reynolds number from 2400 to 22400.The velocities of the crossflow change from 10 to 40m/s, with Weber number of from 1.6 to 25.6, that is to say the momentum ratio between the air and the liquid is from 5 to 127.The frame of the high speed camera is 2000 and the exposure time is 16s.The experimental studies have found that:the differences of Weber number of the crossflow will change the fragmentation behavior of the liquid jet and the dimensionless surface wave length is proportional to the-0.31 power exponent of the Weber number of the crossflow.The distance of the fracture point of liquid column along the direction of the crossflow decreases with the increase of the momentum ratio of the liquid to the air, while it along the initial direction of liquid jet increases with that momentum.The velocity of the droplets produced after fracture on the direction of the crossflow is about 0.1 times as high as that of the crossflow, while it on the direction of initial liquid jet increases linearly with the momentum ratio of the liquid to air firstly, until it becomes 0.8 times of the velocity of initial liquid jet.Based on the above study, this paper had fitted the relation between the wavelength and the Weber number of the crossflow; and also the position of fracture point of the jet, the trajectory of jet, the velocities of produced droplets along with the initial conditions.

-

表 1 穿透深度关系式拟合结果表

Table 1. Penetration result summary

文献编号 穿透深度关系式 6 y/d=4.3(q·x/d)0.33 7 y/d=3.79q0.475(x/d)0.195We-0.068 8 y/d=We-0.05q0.5(1.46ln(x/d)+1.5) 9 y/d=0.92q0.5(x/d)0.33 10 y/d=1.559q0.52ln(1+1.66x/d) 11 y/d=2.207q0.409(x/d)0.421 12 y/d=1.509q0.44ln(1+1.14x/d) 13 y/d=6.13q0.43(x/d)0.23 14 y/d=0.167q0.31(x/d)0.31Rej0.14 注:y:轴向破碎距离, mm; x:横向破碎距离, mm; q:液气动量比; d:实验用喷嘴直径, mm; j:液体射流; We:韦伯数; Re:雷诺数 表 2 实验工况及参数设置

Table 2. Experimental parameters

参数名称和单位 参数值 温度T/K 293 喷嘴孔径d/mm 1 液体密度ρj/(kg·m-3) 997 气体密度ρg(kg·m-3) 1.17 液体射流速度vj/(m·s-1) 2~20 横向气流速度vg/(m·s-1) 10~40 液体粘度μj/(10-6Pa·s) 866 表面张力系数σ/(10-3Nm-1) 70.9 液体射流雷诺数Rej 2400~22400 气流韦伯数Weg 1.6~25.6 液气动量比q 5~127 射流Ohnesorge数Oh 0.0026 高速相机帧幅f 2000 高速相机曝光时间/s 16 -

[1] Ashgriz N, Yarin A L, Yarin A L, et al. Handbook of atomization and sprays[M]. Springer US, 2011:79-80. [2] Wu P K, Kirkendall K A, Fuller R P, et al. Breakup processes of liquid jets in subsonic crossflows[J]. Journal of Propulsion & Power, 2015, 13(1):64-73. http://cat.inist.fr/?aModele=afficheN&cpsidt=10620666 [3] Samir T, San-Mou J, Hukam M, et al. Liquid jets in subsonic crossflow[C]. AIAA Aerospace Sciences Meeting and Exhibit, 2005, 2(1): 34-37. [4] Schetz J A, Ranger A A. Aerodynamic shattering of liquid drops[J]. AIAA Journal, 1969, 7(2):285-290. doi: 10.2514/3.5087 [5] Lubarsky E, Shcherbik D, Bibik O, et al. Fuel jet in cross flow-experimental study of spray characteristics[M]. Advanced Fluid Dynamics, 2012:176-177. [6] Bellofiore A, Cavaliere A, Ragucci R. Air density effect on the atomization of liquid jets in crossflow[J]. Combustion Science & Technology, 2007, 179(1):319-342. https://www.researchgate.net/publication/245312136_Air_density_effect_on_the_atomization_of_liquid_jets_in_crossflow [7] Ragucci R, Bellofiore A, Cavaliere A. Breakup and breakdown of bent kerosene jets in gas turbine conditions[J]. Proceedings of the Combustion Institute, 2007, 31(2):2231-2238. doi: 10.1016/j.proci.2006.07.204 [8] Bellofiore A. The penetration characteristics of normally injected kerosene liquid jet in high weber number flow[C]. 45th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, 2007, 16(4): 71-82. https://www.sciencedirect.com/science/article/pii/S0264127516310528 [9] Chen T, Smith C, Schommer D, et al. Multi-zone behavior of transverse liquid jet in high-speed flow[C]. 31st AIAA Aerospace Sciences Meeting and Exhibit, 2013, 2: 122-129. [10] Wang Q, Mondragon U M, Brown C T, et al. Characterization of trajectory, break point, and break point dynamics of a plain liquid jet in a crossflow[J]. Atomization & Sprays, 2011, 21(3):203-219. https://www.researchgate.net/publication/309107103_Evaluation_of_column_breakpoint_and_trajectory_for_a_plain_liquid_jet_injected_into_a_crossflow [11] Amighi A, Eslamian M, Ashgriz N. Trajectory of a liquid jet in high pressure and high temperature subsonic air crossflow[J]. Proceedings of Iclass, 2009, 1(3):211-218. http://www.dl.begellhouse.com/journals/6a7c7e10642258cc,1f4f813466ce2d6b,7c27430f23c50712.html [12] Tambe S, Jeng S M, Mongia H, et al. Liquid jets in subsonic crossflow[J]. AIAA Journal, 2004, 15(9):56-71. https://etd.ohiolink.edu/!etd.send_file?accession=ucin1100876702&disposition=inline [13] Yoon H J, Hong J G, Lee C W, et al. Correlations for penetration height of single and double liquid jets in cross flow under high-temperature conditions[J]. Atomization & Sprays, 2011, 21(8):673-686. https://www.researchgate.net/publication/269624724_Correlations_for_penetration_height_of_single_and_double_liquid_jets_in_cross_flow_under_high-temperature_conditions [14] Phillips J C, Pch M, Thomas N H. Air flow and droplet motions produced by interaction of flat-fan sprays and cross flows[J]. Atomization & Sprays, 2000, 10(1):83-104. https://www.sciencedirect.com/science/article/pii/S0168169909002282 [15] 万云霞, 黄勇, 朱英.液体圆柱射流破碎过程的实验[J].航空动力学报, 2008, 23(2):208-214. http://www.doc88.com/p-4502158177738.htmlWan Y X, Huang Y, Zhu Y. Experiment on the breakup process of free round liquid jet[J]. Journal of Aerospace Power, 2008, 23(2):208-214. http://www.doc88.com/p-4502158177738.html [16] Less D M, Schetz J A. Transient behavior of liquid jets injected normal to ahigh-velocitygas stream[J]. AIAA Journal, 2015, 24(24):1979-1986. https://www.researchgate.net/publication/234393341_Transient_behavior_of_liquid_jets_injected_normal_to_a_high-velocity_gas_stream -

下载:

下载: